Şalt News

In today’s industry, the key to competition is making production processes error-free and traceable. Having electricity alone is not enough; that energy must be managed wisely. Şalt Otomasyon, as a Konya automation company, plays a critical role in the digital transformation of factories. With our experience in industrial automation systems, we control all processes from raw material to final product.

Konya is the capital of the agricultural industry. With this in mind, we produce high-precision solutions for grain and food processing facilities. In our Feed Mill Automation projects, every step from dosing to packaging is controlled with millimeter accuracy. Similarly, our Bulgur Automation and Steel Silo Automation systems allow you to monitor critical data such as product moisture and temperature in real-time.

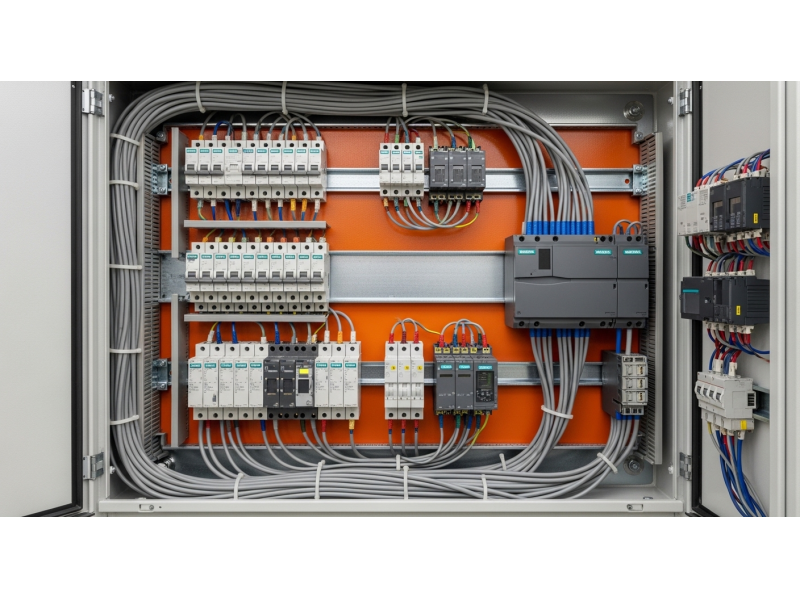

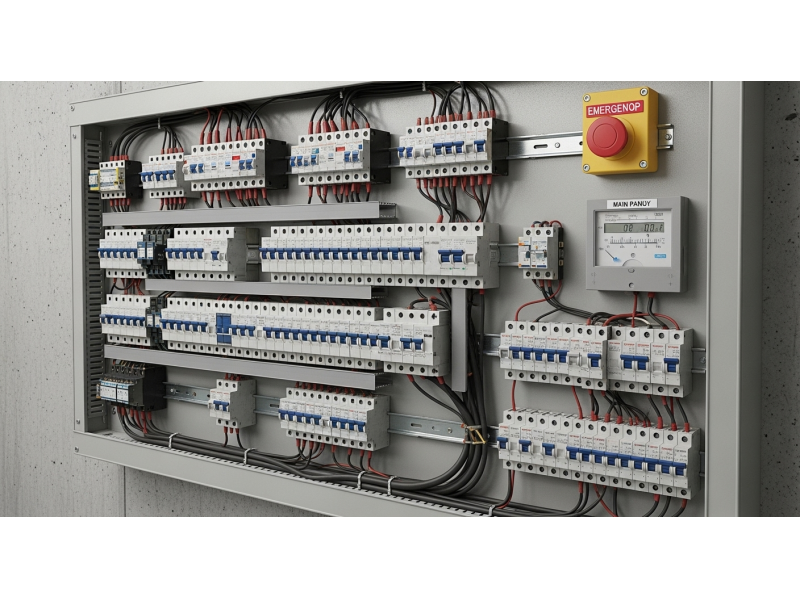

We set up SCADA systems to manage these facilities, allowing operators to control the entire factory from a single screen. In addition, with PCC (Process Control Automation), we minimize human errors and standardize product quality.

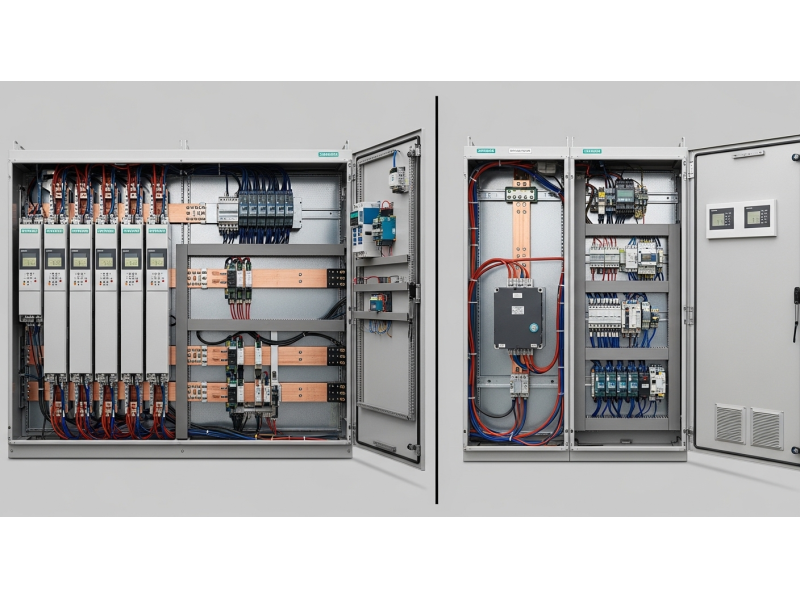

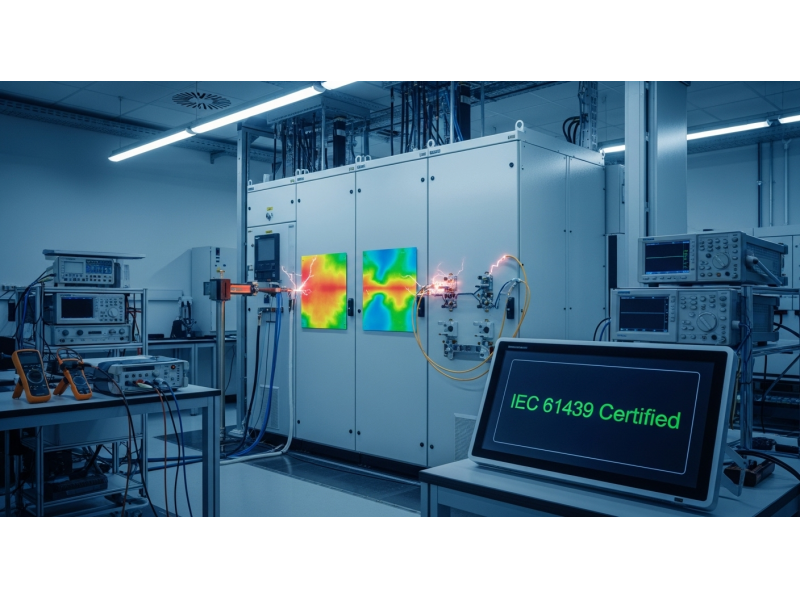

Sustainability is essential for modern facilities. In our Biogas Automation and Wastewater Treatment & Water Preparation Automation projects, we process environmental data to ensure facilities operate efficiently and comply with legal regulations. On the energy production side, PV Distribution Panels safely transfer renewable energy to the grid, and Frequency Converter Panels ensure motors consume only the energy they need, saving costs.

High temperatures and heavy industry conditions require specialized expertise. In risky processes like Boiler Automation and Galvanization Automation, we use PLC control panels and redundant systems to maximize workplace safety.

As Şalt Elektrik, we provide all your automation material supply and engineering support under one roof.